CopaData Connector

The integration of MES (Manufacturing Execution System) layer with shop floor automation/SCADA is crucial for optimizing manufacturing processes. The COPA-DATA zenon Connector realizes a direct communication between Tulip and COPA-DATA zenon software platform, covering a vital step towards digitized manufacturing. This integration is essential because it enables real-time monitoring and control of production activities, enhances data visibility, and supports informed decision-making. This connector lays the foundation for a scalable solution, enabling meaningful integration of manufacturing operations.

By bridging the gap between MES and shop floor automation, SCADA, or Process Orchestrators (MTP POL), organizations can achieve improved productivity, quality, and responsiveness, driving overall operational excellence.

Connect Tulip apps to COPA-DATA zenon software platform

Jörn Volckmann, Assoc. Director

Business Advisory, Innovation & Global (Tulip) Practice Lead

Introducing Jörn, a pharma industry veteran, ISPE member and speaker, and driving force behind our success in the pharma and biotech space. With his extensive experience and knowledge, Jörn has become a key player in our team, bringing valuable insights and expertise to our operations. His passion for innovation and dedication to excellence have helped us to stay ahead of the curve and continue to deliver exceptional results for our customers.

COPA-DATA zenon Integration

Table of contents

- Introduction

- Network Considerations

- COPA-DATA zenon Configuration

- Tulip Configuration

- Connector Functions

Introduction

zenon is a

software platform developed by COPA-DATA, primarily used in the field of

supervisory control and data acquisition (SCADA),

human-machine interface (HMI),

Process Orchestration (MTP POL) and historian systems.

zenon

offers a comprehensive set of tools for visualization, process control, and

data acquisition in industrial environments. It allows users to monitor and

control various processes and machinery in real-time, providing insights into

production processes, energy management, and quality control.

In the

present document we will walk you through a generally applicable yet simplified

process of bi-directional data exchange between a

manufacturing system (Tulip)

and Automation (COPA-DATA zenon).

In case you need assistance in realizing more complex interfacing scenarios please feel free to contact us.

Network Considerations

In case COPA-DATA zenon is hosted in the public cloud no specific networking setup is necessary.

In case COPA-DATA zenon is hosted on-premises appropriate access has to be set up for the Tulip to communicate through the local host (e. g. firewall rules adjustment -> “whitelisting” of Tulip’s IP) or respective Connector Host setup (Link: https://support.tulip.co/docs/introduction-to-tulip-connector-hosts)

COPA-DATA zenon Configuration

Prerequisites:

zenon IIoT Services

must be installed and licensed in zenon software platform in order to enable IIoT

API (REST interface).

Minimum zenon version supported is v.12

Configuration:

- IIoT Services must be configured in zenon engineering studio.

- Access from external APP (Tulip) need to be configured in zenon IIoT Service Configuration Studio.

zenon IIoT API needs Token authentication.

Swagger open API documentation is available on request.

By using IIoT API, is it possible:

- Reading real time process variables from zenon:

- Writing process variables to zenon

- Querying real time and historical Alarms

- Querying Audit Trails

- Querying Time Series Data.

REST API calls parametrization must consider the zenon project resources like, Project ID, Variables Names, Alarms group/class, Archives name, etc.

For more

information about zenon IIoT API, please refer to COPA-DATA online help:

https://onlinehelp.copadata.com/Content.html?product=supervisor&version=1400&lang=en&id=E1100620EE48F0B7E4D6F688455F4F15F5BDA4C0527721B926982D207329A7C4

zenon engineer should provide project information in order to correctly call IIoT API from 3rd part APP.

For more

information about zenon software platform configuration and features, please

refer to COPA-DATA online help:

https://onlinehelp.copadata.com or access to COPA-DATA Academy: https://www.zenon-academy.com/

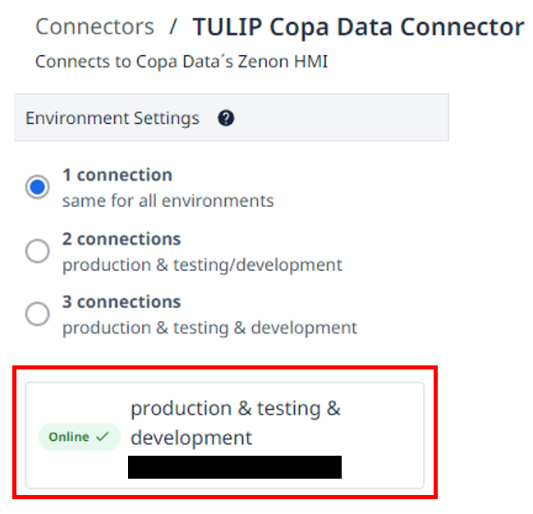

Access the Connectors menu in Tulip and click on the TULIP Copa Data Connector configuration.

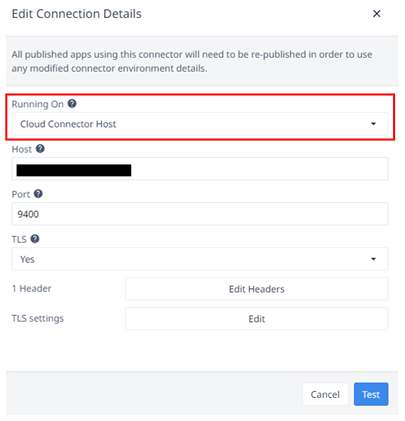

Set the "Running on" field to “Cloud Connector Host” (depending on your connector host setup: https://support.tulip.co/docs/introduction-to-tulip-connector-hosts) choosing from the drop-down list

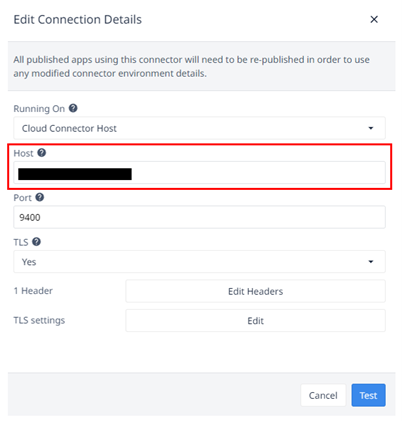

Set the Host to the IP of your COPA-DATA zenon X

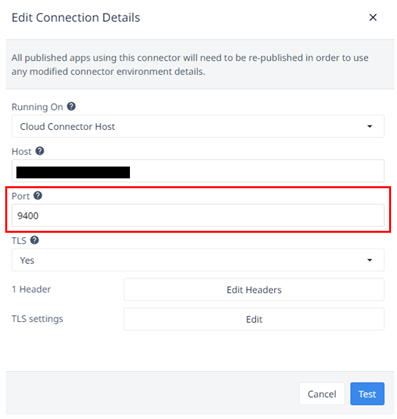

Set the Port to "9400" as indicated in the COPA-DATA zenon documentation.

Subsequently the connection should be tested and assured that it is functional.

Connector Function

The present connector is using the REST API and its standard functions GET, PUT, POST and DELETE.

The following automation related generic interactions have been implemented in this Connector.

In

real-life scenarios usually more complex interactions could be required that

can be achieved extending the present connector and its functions.

In case you

need assistance in realizing the more complex scenarios please feel free to

contact us.

Filling

& Packaging Function

According

to the common scenario the manufacturing system is the master

for the Work Order (WO) management. In case of a

complex automation (e.g. SCADA

or DCS/PCS) the manufacturing system usually triggers the WO start and releases

the batch after completion of the WO.